QR Code

About Us

Products

Contact Us

Phone

Fax

0086-574-87527773

E-mail

Address

No 432 Zhenhai Middle Road, Luotuo Street, Zhenhai District, Ningbo City, Zhejiang China

In today's industrial landscape, the choice of insulation materials can significantly impact efficiency, safety, and overall performance.

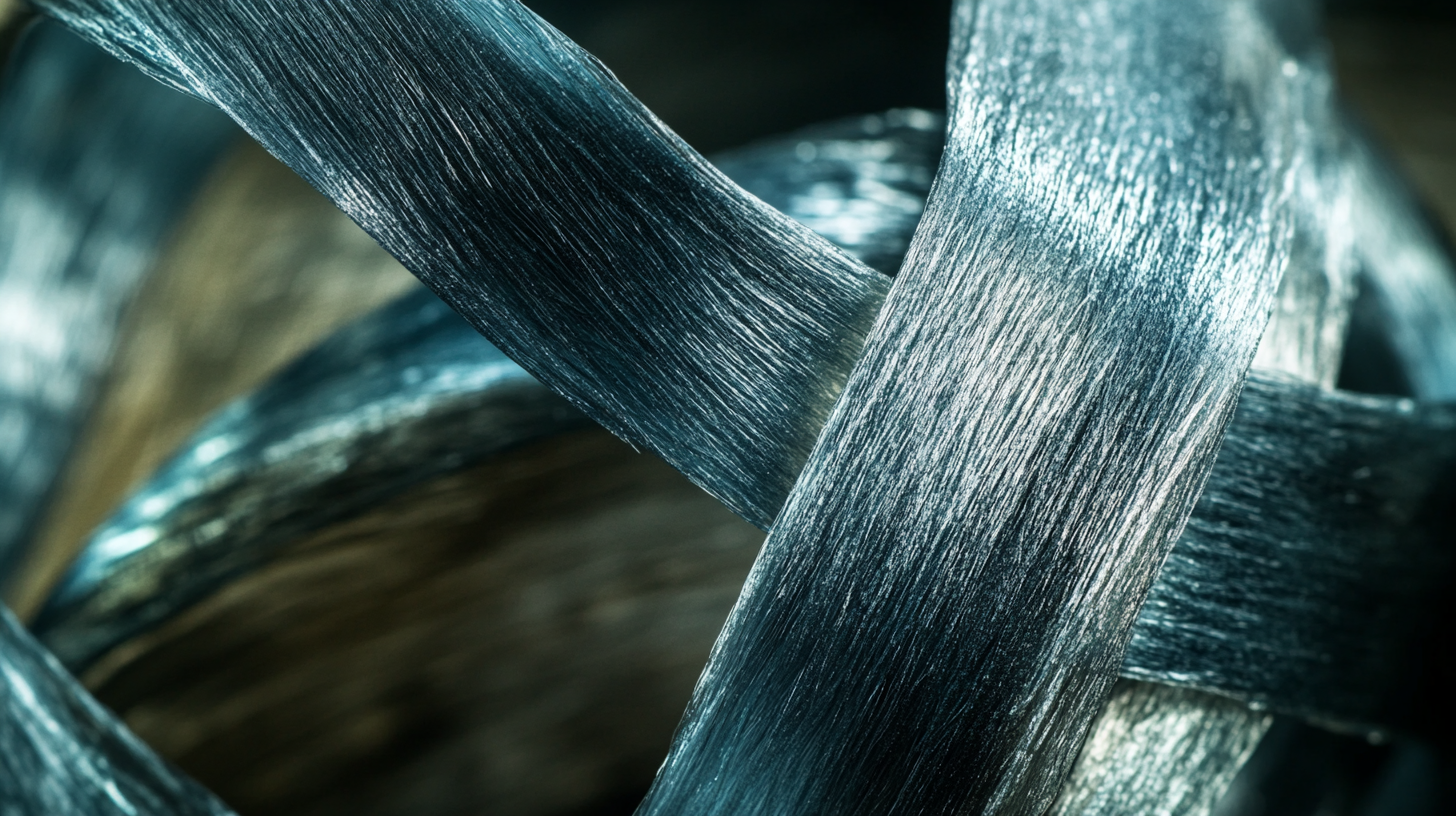

Mica Tape Insulation stands out as a premier solution, especially in high-temperature environments where reliability and durability are pivotal.

According to recent industry reports, the global insulation market is projected to reach $70 billion by 2027, with a notable rise in demand for advanced thermal insulation products, particularly those that can withstand extreme conditions.

Mica Tape Insulation not only meets these stringent requirements but also offers unique advantages like excellent thermal resistance, electrical insulation properties, and mechanical strength.

With industries increasingly seeking resilient yet efficient insulation solutions, understanding the real-world applications and benefits of

Mica Tape Insulation becomes essential for making informed decisions that align with industrial needs.

Mica tape insulation has emerged as a crucial component in various industrial applications, particularly in the field of electrical insulation. One of its standout features is its exceptional thermal resistance, which can endure temperatures up to 1000°C. According to a report by MarketsandMarkets, the global electrical insulation market is projected to reach $77.27 billion by 2025, with mica tape leading the way due to its outstanding performance in high-temperature environments. This makes it an ideal choice for industries such as power generation and motor manufacturing, where reliable thermal management is paramount.

In addition to its thermal stability, mica tape provides excellent dielectric strength, making it highly effective in preventing electrical breakdown. A recent study from the International Journal of Electrical Engineering noted that mica-based insulation systems exhibited higher breakdown voltages compared to conventional alternatives, ensuring enhanced safety and longevity of electrical equipment. Furthermore, the resistance to chemical and mechanical stresses of mica tape contributes to overall system efficiency, reducing the need for frequent maintenance and replacements, thereby lowering operational costs in the long run. With these compelling benefits, mica tape stands out as a preferred insulation material in demanding industrial settings.

When selecting a high-quality mica tape manufacturer for your industrial needs, several key factors come into play. First and foremost, evaluate the manufacturer's experience and expertise in the field. An established company with a proven track record is more likely to produce superior products that meet industry standards. Additionally, investigate their production techniques and ensure they use advanced technology to guarantee the consistent quality of mica tape.

Another crucial aspect to consider is the range of products offered by the manufacturer. A reputable supplier should provide a variety of mica tape options tailored to different applications, such as electrical insulation or high-temperature resistance. This versatility will allow you to find the perfect fit for your specific requirements.

Tip: Always ask for samples before making a bulk purchase. Testing the insulation under real-world conditions can help you assess the performance and durability of the mica tape. Furthermore, don’t hesitate to request certifications and quality assurance documentation to ensure the manufacturer adheres to stringent industry standards.

Mica tape has emerged as a vital material for various industrial applications due to its superior insulation properties and fire-resistant capabilities. One primary reason to choose mica tape is its unparalleled electrical insulation, making it essential for safeguarding high-performance cabling in today’s infrastructure. With the increasing emphasis on safety and efficiency, industries are leveraging mica tape to enhance the reliability of electrical systems, ensuring they meet the rigorous demands of modern operations.

Moreover, mica tape's thermal insulation capabilities play a crucial role in various applications. It maintains performance under extreme temperatures, which is increasingly important as industries push for higher efficiency and sustainability. The global mica tape market is projected to grow substantially, reflecting the rising demand for materials that can withstand challenging conditions without compromising performance. As industries evolve, integrating mica tape into their processes not only boosts safety but also ensures compliance with evolving regulatory standards.

| Application | Mica Tape Type | Temperature Rating (°C) | Dielectric Strength (kV/mm) | Application Benefits |

|---|---|---|---|---|

| Electric Motors | Mica/Glass Tape | 650 | 20 | Outstanding thermal stability |

| Transformers | Mica/Polyester Tape | 500 | 22 | Excellent electrical insulation |

| Generators | Mica Paper Tape | 600 | 25 | High mechanical strength |

| Electrical Cabling | Flexible Mica Tape | 300 | 15 | Good flexibility and ease of application |

| Heat Shields | Mica Insulation Tape | 700 | 18 | High temperature resistance |

| Induction Heating Equipment | Thermal Mica Tape | 800 | 30 | Superior heat dissipation |

| Railway Signaling | Mica Adhesive Tape | 450 | 17 | Durability against harsh environments |

Mica tape insulation has become a cornerstone in various industrial applications, primarily due to its superior thermal and electrical properties. One prominent area where mica tape shines is in the manufacturing of electric motors and generators. These devices generate substantial heat, and mica tape's excellent heat resistance facilitates efficient performance while protecting critical components from damage. Its ability to withstand high temperatures, often exceeding 1000°C, ensures longevity and reliability in challenging environments, making it an ideal choice for industries reliant on these technologies.

Another critical application of mica tape insulation is within the automotive sector, especially in electric vehicles where battery thermal management is essential. Mica tape not only provides electrical insulation but also serves as a barrier against heat, improving the overall safety and performance of battery systems. Furthermore, its lightweight nature and excellent machinability allow for seamless integration into various components, thereby enhancing efficiency. As industries continue to seek sustainable and durable solutions, mica tape insulation is proving to be an invaluable asset in modern manufacturing processes.

Mica tape insulation is increasingly recognized as a solution to several common industrial challenges, particularly in environments exposed to high temperatures and electrical stress. According to a report by Frost & Sullivan, the global electrical insulation market is projected to reach $100 billion by 2025, driven largely by increased demand for heat-resistant materials such as mica tape. This insulation type effectively withstands temperatures exceeding 1000°F, making it ideal for use in industries such as power generation, automotive, and aerospace, where conventional materials often fail.

In addition to its thermal properties, mica tape insulation offers excellent electrical insulation, which is critical for preventing equipment failure and maintaining safety standards. The latest data from the International Electrotechnical Commission indicates that electrical insulation failures account for nearly 30% of unplanned downtime in manufacturing, leading to significant losses. By incorporating mica tape, industries can minimize these risks, ensuring operational efficiency while also complying with stringent safety regulations. With its durability and versatility, mica tape insulation stands out as an essential resource in tackling today's industrial challenges.

0086-574-87527773

No 432 Zhenhai Middle Road, Luotuo Street, Zhenhai District, Ningbo City, Zhejiang China

Copyright © 2015-2024 Ningbo Nafty Sealing Materials Co., Ltd. All Rights Reserved.

| | | XML | Privacy Policy |

TradeManager

Skype

VKontakte