QR Code

About Us

Products

Contact Us

Phone

Fax

0086-574-87527773

E-mail

Address

No 432 Zhenhai Middle Road, Luotuo Street, Zhenhai District, Ningbo City, Zhejiang China

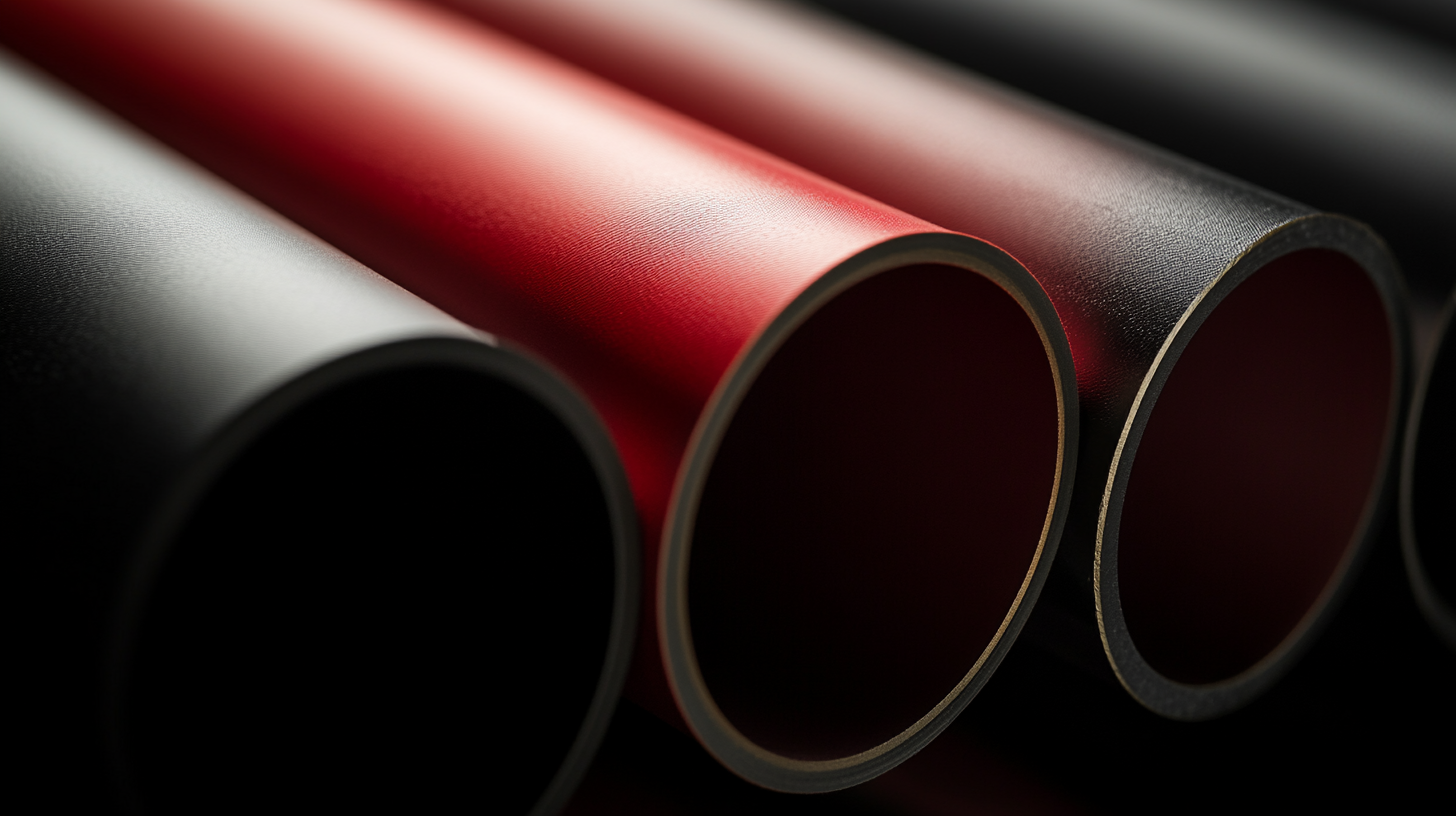

In the ever-evolving landscape of global industries, the demand for high-quality materials has never been more critical. One such material that stands out for its unique properties and versatile applications is mica tube. Understanding the mica tube purpose is essential for manufacturers and engineers alike, as these tubes serve as vital components in various sectors, from electronics to automotive industries. This blog delves into the crafted excellence of mica tubes produced in China, exploring their superior performance and reliability. We will provide insightful tips on selecting the right mica tube for specific applications, ensuring that industries can leverage the full potential of this remarkable material. By highlighting the intricacies of mica tube production and its global impact, we aim to empower companies to make informed decisions that enhance efficiency and innovation in their operations.

Mica tube manufacturing has seen a remarkable evolution in recent years, particularly in China, where advanced technology and skilled labor have combined to produce high-quality products that meet the demands of various global industries. China’s dominance in mica tube production can be attributed to its vast natural mica resources, efficient manufacturing processes, and commitment to continuous innovation. As industries worldwide seek reliable and durable mica tubes for applications ranging from electrical insulation to decorative uses, China stands at the forefront, providing solutions that cater to specific needs.

**Tips:** When sourcing mica tubes, it's essential to consider the certifications of the manufacturer to ensure compliance with international standards. Additionally, evaluating the supplier's production capacity can guarantee timely delivery for large-scale projects. Another useful tip is to inquire about customization options, as many manufacturers offer tailored products that suit particular application requirements.

The global market's reliance on China's mica tubes highlights the strategic importance of this sector. The country's investments in research and development enhance its ability to adapt to changing market trends and consumer preferences. As sustainability becomes a critical focus, many Chinese manufacturers are also exploring eco-friendly practices in mica extraction and production, reinforcing their competitive edge and appeal to environmentally conscious clients.

**Tips:** When engaging with a supplier, ask about their sustainability practices and sourcing methods to ensure that they align with your company's values. Moreover, consider leveraging trade shows and industry events to gain insights into emerging trends and innovations in mica tube manufacturing.

| Dimension (mm) | Application | Market Demand (Units/Year) | Export Value (USD) |

|---|---|---|---|

| 10 x 15 | Electronics Insulation | 500,000 | $1,200,000 |

| 20 x 30 | Industrial Applications | 300,000 | $800,000 |

| 15 x 25 | Aerospace Components | 200,000 | $600,000 |

| 25 x 40 | Automotive Industry | 150,000 | $500,000 |

| 30 x 50 | Energy Sector | 100,000 | $300,000 |

In the competitive landscape of global industries, the demand for high-quality materials has never been more critical. Mica tubes, known for their excellent thermal and electrical insulation properties, are increasingly recognized for their versatility and reliability. To maintain superior standards, manufacturers in China have implemented rigorous quality control measures throughout the production process. From raw material selection to final inspections, these controls ensure that each mica tube meets the specific needs of various industrial applications.

The production of mica tubes involves several stages, each subject to stringent quality checks. Advanced testing methods, including dimensional accuracy assessments and thermal resistance evaluations, guarantee that the products can withstand extreme conditions. Additionally, manufacturers employ skilled technicians who monitor every step of the process, ensuring that any potential issues are identified and rectified promptly. By embracing these comprehensive quality control measures, Chinese manufacturers not only enhance the performance of mica tubes but also solidify their reputation in the global market as a reliable source of excellence.

The global mica tube market is experiencing significant growth, driven by its versatile applications across various end-use sectors. According to a recent report by Market Research Future, the mica tube market is projected to expand at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth trajectory underscores the increasing demand for high-performance materials, particularly in industries such as cosmetics, electronics, and automotive, where mica tubes are valued for their thermal resistance and insulating properties.

In the cosmetic sector, the demand for mica tubes is projected to rise sharply, spurred by consumers' growing preference for natural and mineral-based products. A study by Allied Market Research indicates that the global cosmetic industry is expected to reach over $800 billion by 2025, with a notable shift towards sustainable and eco-friendly packaging solutions. This trend is likely to boost the adoption of mica tubes, which not only enhance product shelf life but also align with environmentally conscious consumer behavior.

Furthermore, the electronics industry is witnessing a surge in the application of mica tubes, particularly in the manufacturing of capacitors and insulators. The International Electrotechnical Commission forecasts a robust growth rate of 6% for electronic components through 2025. As innovations in technology continue to advance, the demand for reliable and efficient insulating materials like mica tubes will maintain its upward trend, solidifying their role in the global supply chain.

In recent years, the mica tube manufacturing industry in China has made significant strides toward environmental sustainability. With the increasing demand for eco-friendly materials across various global industries, manufacturers are innovating processes that reduce waste and energy consumption. According to a 2022 report by the International Industrial Sustainability Association, companies that embrace sustainable practices see a 15% increase in operational efficiency and a 20% improvement in their brand reputation.

One notable aspect of mica tube production is the use of advanced recycling technologies that convert waste mica into high-quality products. This innovation is not only pivotal for reducing environmental impact but also for meeting the growing consumer preference for sustainable goods. A study published by the Global Mica Alliance indicates that the sustainable mica market is expected to grow by 30% over the next five years, highlighting the potential for manufacturers in China to lead the way in this sector.

Interestingly, the design of industrial spaces, such as the recent geometric skylights at the Blue Insight Cave in Ningde City, illustrates a commitment to sustainability in the built environment. These designs reflect how sustainable practices can extend beyond product manufacturing into architecture and urban planning, emphasizing a comprehensive approach to environmental responsibility that intertwines with industry innovations.

Mica tube exports from China have emerged as a pivotal element in reinforcing global supply chains. These tubes, known for their electrical insulation properties and mechanical strength, are integral in various industries, including electronics, automotive, and construction. By providing cost-effective and high-quality mica tubes, Chinese manufacturers are not only catering to localized demands but are also bolstering the economic fabric of international markets. This has led to a strengthened interdependence among industries worldwide.

The economic impact of mica tube exports is profound, contributing to job creation and technological advancement in both exporting and importing regions. As companies increasingly rely on these essential components for their production processes, the demand for quality mica tubes continues to rise. This trend fosters a collaborative spirit among global manufacturers, facilitating innovation and efficiency in product design and supply chain management. Ultimately, the export of mica tubes from China exemplifies how localized production can effectively meet the diverse needs of global industries while driving economic growth on multiple fronts.

This chart illustrates the increasing economic impact of mica tube exports from China over the past five years. The consistent growth indicates a strengthening of global supply chains as industries worldwide rely more on these products.

0086-574-87527773

No 432 Zhenhai Middle Road, Luotuo Street, Zhenhai District, Ningbo City, Zhejiang China

Copyright © 2015-2024 Ningbo Nafty Sealing Materials Co., Ltd. All Rights Reserved.

| | | XML | Privacy Policy |

TradeManager

Skype

VKontakte