QR Code

About Us

Products

Contact Us

Phone

Fax

0086-574-87527773

E-mail

Address

No 432 Zhenhai Middle Road, Luotuo Street, Zhenhai District, Ningbo City, Zhejiang China

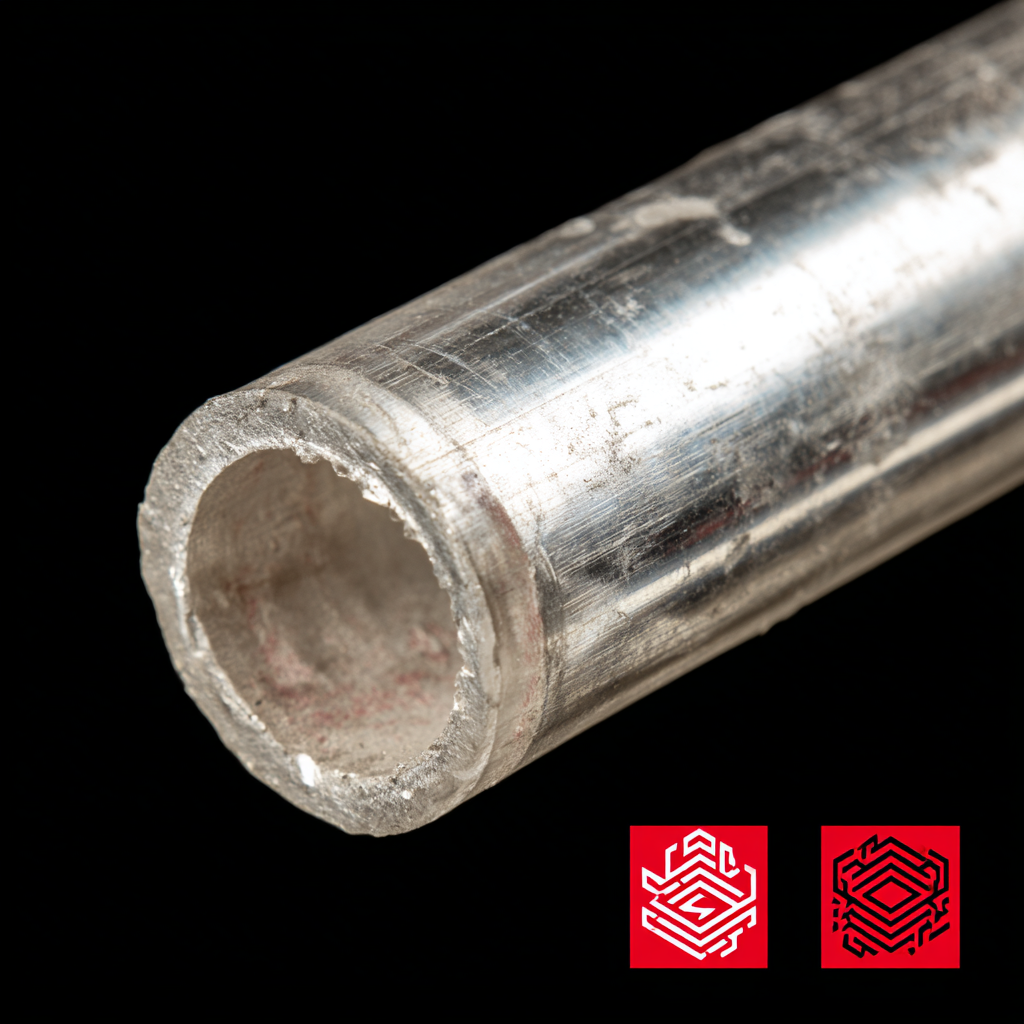

In today's world, the demand for high-quality mica tubes is rapidly increasing, driven by their versatile applications across various industries. This blog delves into the exceptional craftsmanship and unmatched quality of mica tubes produced in China, which cater to global excellence. Understanding the mica tube purpose is essential for any business looking to enhance their product offerings, as these tubes serve as vital components in electrical insulation, thermal protection, and various industrial applications. By exploring the unique qualities and manufacturing processes of mica tubes, we aim to provide valuable insights that will not only illuminate their indispensable role in modern technology but also guide you in making informed decisions when sourcing these materials for your business needs.

Mica tubes are gaining significant attention across various industries due to their unique properties and versatility. They are celebrated for their exceptional thermal and electrical insulation, making them invaluable in electronics, automotive, and aerospace applications. Manufacturers are increasingly recognizing the importance of these tubes in enhancing product quality and ensuring durability. The global market is witnessing a demand surge for high-quality mica tubes, particularly those crafted with precision in China, which are known for their unmatched quality.

Tips for leveraging mica tubes include ensuring compatibility with the specific application, as different industries may require varying specifications. Additionally, consider the treatment and finishing of mica tubes to enhance their performance in high-temperature scenarios. Understanding the material properties and potential health benefits, such as their non-toxic nature, can also guide industries toward making informed decisions for safe and effective usage.

Furthermore, industries should explore the intersection of modern technology and traditional materials. Incorporating nanotechnology into mica tube production could revolutionize their application, offering advanced functionalities that adhere to the evolving demands of global markets. Embracing these innovations not only meets contemporary needs but also positions companies at the forefront of sustainable and efficient manufacturing practices.

Chinese mica tubes have gained a reputation for exceptional quality, making them a popular choice for various industries globally. One of the key features that set these mica tubes apart from competitors is their superior thermal resistance. Manufactured using high-grade mica, these tubes can withstand extreme temperatures, making them ideal for electrical insulation applications where performance is critical. The ability to maintain structural integrity under heat ensures the reliability and longevity of products that utilize these tubes.

Another distinguishing feature of Chinese mica tubes is their excellent flexibility and toughness. Unlike many alternatives, these mica tubes can be easily manipulated without compromising their durability. This characteristic is particularly beneficial in industries that require custom sizes or shapes for specific applications. Additionally, the meticulous crafting process in China enhances the purity of the mica used, minimizing impurities and ensuring a consistent product that satisfies stringent industrial standards. These factors contribute to a significant competitive edge, as manufacturers can rely on the performance and customization options that Chinese mica tubes offer, ultimately supporting a wide range of innovative applications.

Ensuring exceptional quality in the crafting of mica tubes is imperative for achieving global excellence. Manufacturers in China employ stringent quality control measures throughout the entire production process. From the sourcing of raw materials to the final product, every step is meticulously monitored. This not only ensures the durability and efficiency of the mica tubes but also helps in minimizing environmental impact—a crucial aspect given the recent discussions surrounding mica mining in protected areas.

Tips for ensuring quality in mica tube production include regular inspections and audits of the supply chain, combined with comprehensive training programs for staff involved in the manufacturing process. Furthermore, adopting advanced processing technologies can significantly enhance the quality of the final output. For instance, companies might consider investing in innovative grinding and screening devices to optimize the handling of mica materials.

Adopting sustainable practices is another critical measure. By utilizing eco-friendly water washing methods and minimizing waste, manufacturers can produce high-quality mica tubes while supporting environmental conservation. It is essential for businesses to align their production methods with global sustainability goals, ensuring their products are not only superb in quality but also eco-conscious.

| Dimension | Measurement (mm) | Weight (g) | Mica Content (%) | Application Area | Quality Control Measure |

|---|---|---|---|---|---|

| Outer Diameter | 10 | 50 | 98 | Electrical Insulation | Visual Inspection |

| Inner Diameter | 8 | 40 | 97 | Thermal Shielding | Thickness Testing |

| Length | 100 | 80 | 99 | Chemical Resistance | Moisture Testing |

| Wall Thickness | 1 | 10 | 95 | Construction | UV Resistance Testing |

Mica tubes, renowned for their exceptional thermal and electrical insulation properties, are increasingly finding applications across various global markets. Industries such as electronics, automotive, and construction leverage these high-quality products to enhance performance and reliability. In electronics, mica tubes are crucial for insulating wires and components, ensuring safe operation in devices ranging from household appliances to high-end technology. Their ability to withstand high temperatures and resist electrical breakdown makes them an ideal choice for modern applications.

Mica tubes, renowned for their exceptional thermal and electrical insulation properties, are increasingly finding applications across various global markets. Industries such as electronics, automotive, and construction leverage these high-quality products to enhance performance and reliability. In electronics, mica tubes are crucial for insulating wires and components, ensuring safe operation in devices ranging from household appliances to high-end technology. Their ability to withstand high temperatures and resist electrical breakdown makes them an ideal choice for modern applications.

Moreover, the mica industry's dynamics are influenced significantly by ongoing global discussions about ethical sourcing and environmental sustainability. The demand for mica, particularly in cosmetics and electrical applications, has led to increased scrutiny regarding mining practices and their impact on communities, especially children. It is essential for consumers and manufacturers alike to be aware of the origins of their mica products and advocate for responsible sourcing initiatives. By prioritizing transparency in the supply chain, the industry can contribute to the overall protection of children's rights and promote ethical practices in mica mining.

In recent years, the focus on sustainable practices within the production of mica tubes in China has gained momentum, reflecting a broader trend towards environmental responsibility in manufacturing. As global demand for mica continues to rise, especially in the cosmetics and electronics industries, the need for responsible sourcing has become paramount. Chinese manufacturers are increasingly adopting sustainable techniques, emphasizing eco-friendly extraction methods and improving supply chain transparency to combat issues like greenwashing that have plagued other sectors, such as beauty.

Moreover, the integration of sustainability into mica production not only ensures the conservation of natural resources but also promotes ethical labor practices. By implementing innovative strategies for waste reduction and resource efficiency, the mica industry in China is setting a precedent for sustainable practices. As stakeholders demand greater accountability, the commitment to responsible sourcing and ethical production processes is becoming essential, proving that quality and sustainability can coexist in a competitive global market.

0086-574-87527773

No 432 Zhenhai Middle Road, Luotuo Street, Zhenhai District, Ningbo City, Zhejiang China

Copyright © 2015-2024 Ningbo Nafty Sealing Materials Co., Ltd. All Rights Reserved.

| | | XML | Privacy Policy |

TradeManager

Skype

VKontakte