Blog

Blog

Blog

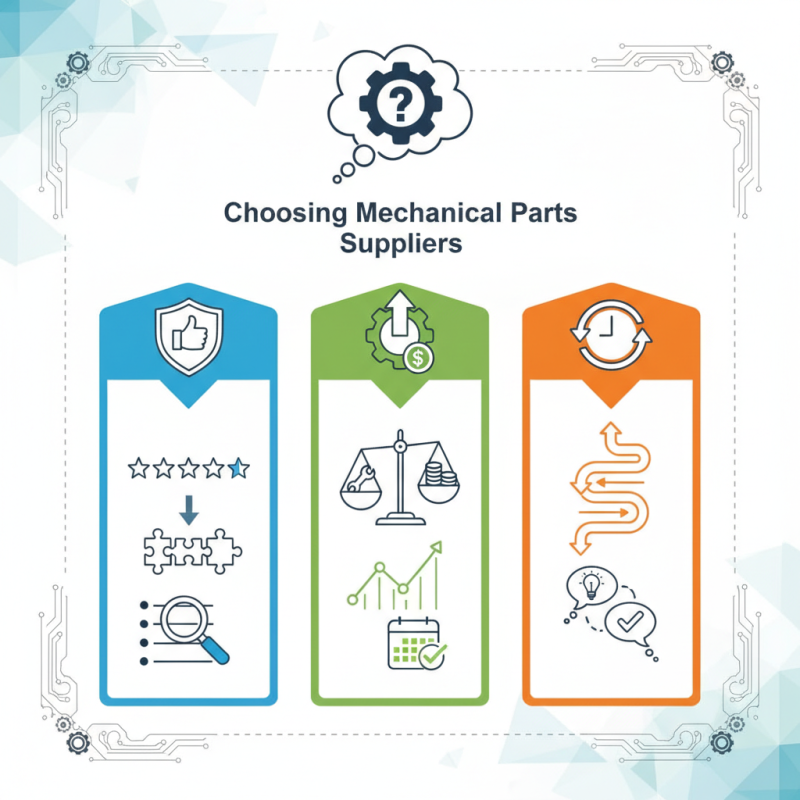

Essential Tips for Choosing the Best Mechanical Parts Suppliers?

Choosing the right mechanical parts suppliers can be challenging. The quality of parts impacts product performance. Poor choices may lead to delays and failures.

When searching for reliable suppliers, consider their reputation. Look for feedback from past clients. A good track record speaks volumes. Also, assess their product range. Diverse offerings indicate expertise.

Price matters, but it isn't everything. Balance cost with quality for the best results. Sometimes, cheaper parts can be costly in the long run. Take the time to research and compare options. Don't rush into decisions. Reflect on your choices to find the best fit.

Understanding Your Mechanical Parts Needs

Understanding your mechanical parts needs is fundamental when selecting suppliers. Begin by identifying the specific components you require. Are they standard pieces, or do you need custom parts? Knowing your specifications helps narrow down potential suppliers. Describe the scope of your project. This will aid in discussions and ensure you get relevant advice.

Consider the materials and tolerances required for your parts. Different applications demand different qualities. For instance, a high-temperature environment will need durable materials. It’s essential to communicate these needs clearly. Suppliers should be able to meet your demands without hesitation. Look for those who recognize quality standards. Sometimes, suppliers might not fully understand your requirements, leading to mismatched components.

Price is important, but don’t let it be the only factor. Lower costs can sometimes mean lower quality. Evaluate the trade-offs carefully. Ask for samples if needed. This provides insight into the supplier’s capabilities. Remember to reflect on past experiences too. Were there issues with delivery times or part specifications? Use those insights to inform your current decisions. Balancing quality, cost, and communication will make a significant difference in your selection process.

Researching Potential Suppliers Thoroughly

When researching potential mechanical parts suppliers, it'scrucial to dig deep. A 2022 industry report highlighted that 70% of companies faced issues due to inadequate supplier vetting. This data emphasizes the need for diligent research. Look beyond surface-level information. Check for certifications and standards compliance. Ensure that suppliers have a proven track record.

You can also gather reviews from other companies. Consider reaching out to past clients to discuss their experiences. Non-disclosure agreements can prevent revealing sensitive information but can be navigated when trust is built. This approach uncovers real-world challenges faced by suppliers.

Tip: Evaluate their production capabilities. A reliable supplier should conduct regular quality checks. Poor quality control can lead to defects and increased costs. Remember that a seemingly great deal could backfire if their parts fail to meet your specifications.

Explore their supply chain logistics too. Timely delivery is as important as product quality. If a supplier often delays shipments, consider it a red flag. Delays can disrupt your operations. Conducting thorough research helps you avoid such pitfalls.

Evaluating Supplier Qualifications and Certifications

When selecting a mechanical parts supplier, evaluating qualifications and certifications is crucial. A report by the International Organization for Standardization shows that 75% of companies faced supply chain disruptions due to unverified suppliers. A robust certification from organizations, such as ISO 9001, ensures adherence to quality management standards. This can significantly reduce risks in production processes.

Many suppliers claim compliance but lack verifiable certifications. A surprising 45% of businesses do not perform thorough checks on their suppliers’ certifications. This negligence can lead to poor product quality and increased costs. Inspecting a supplier's accreditation history, such as their adherence to industry regulations, can help mitigate these risks.

Certifications can vary widely across industries. Therefore, it is essential to identify what specific qualifications are relevant to your needs. For example, in the aerospace sector, AS9100 certification is critical. In contrast, automotive suppliers might require IATF 16949. Comparing these details can reveal discrepancies that may affect your operation. Engaging with suppliers who emphasize transparency can ultimately lead to better partnerships and improved operational efficiency.

Assessing Product Quality and Reliability

When choosing mechanical parts suppliers, product quality and reliability are crucial. A recent study by the Research Institute for Manufacturing indicates that nearly 30% of supply chain disruptions are due to quality issues. High-quality parts are vital for overall performance and durability. Suppliers should have certifications, such as ISO 9001, to demonstrate their commitment to quality management.

Tip: Always request product samples before finalizing your choice. This allows for a practical assessment of materials used and overall craftsmanship. Conducting quality tests can provide insights into long-term reliability.

Evaluate the supplier's track record. A partner with years of experience in your industry is less likely to have quality-related problems. According to industry reports, suppliers with a history of reliability improve production efficiency by up to 25%. Look for reviews and testimonials that reflect past customer experiences.

Tip: Don't overlook communication. A supplier who is responsive is often more reliable. Poor communication can signal potential issues with quality control down the line. Building a strong supplier relationship can lead to better quality assurance.

Comparing Pricing and Delivery Options

When selecting mechanical parts suppliers, pricing and delivery options play vital roles. The cost of parts varies significantly across suppliers. Some may offer lower prices but have hidden fees or higher shipping costs. Always examine the total cost. It's not just about the sticker price. Substantial savings can be lost through poor logistics.

Delivery times are equally important. Some suppliers promise quick shipping but fail to meet deadlines. This can cause production delays. Always inquire about their average shipping times. Ask about their policies for delays. Consider their location too. A supplier closer to your site may provide faster service. Balancing affordability and timely delivery is a challenge.

However, no supplier is flawless. You might encounter unexpected issues. Occasionally, parts may be out of stock or back-ordered. Transparency from suppliers helps. They should communicate openly about stock levels. This creates trust. Review your experiences with different suppliers. Reflect on what worked and what didn’t. Making informed choices requires learning from past partnerships.