Blog

Blog

Blog

Top 10 Uses of Stainless Steel Wire Mesh You Should Know?

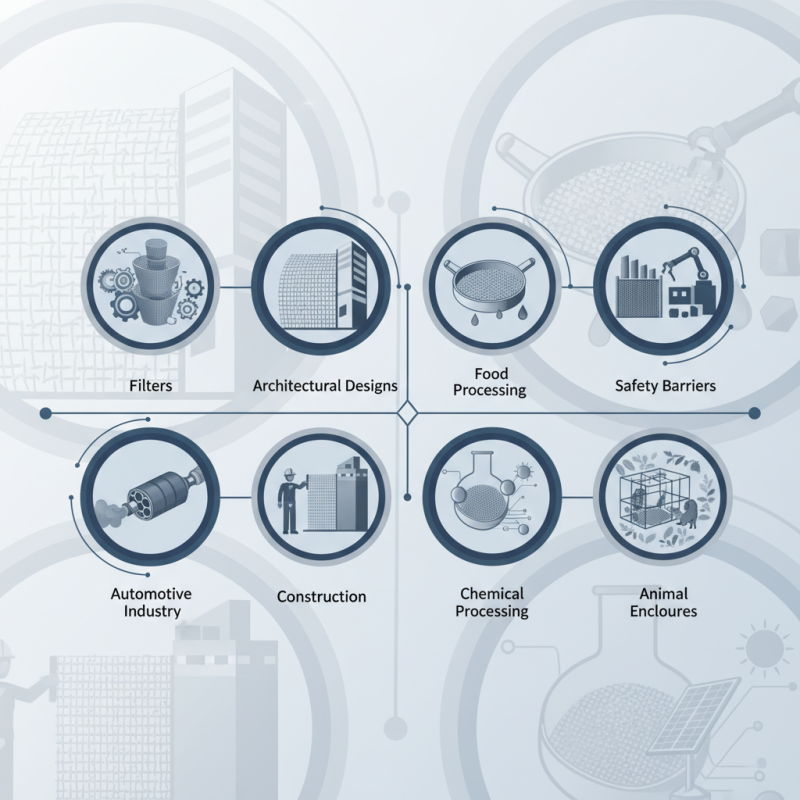

stainless steel wire mesh is a versatile material used across various industries. Its properties, such as corrosion resistance and strength, make it ideal for many applications. According to a recent market report, the stainless steel wire mesh market is expected to grow by 7% annually. This growth is driven by its increased demand in construction, automotive, and food processing sectors.

Several companies are utilizing stainless steel wire mesh for filters, screens, and safety barriers. For example, in the automotive industry, it is used for air filters and catalytic converters. In the food industry, hygiene standards require the use of stainless steel wire mesh for processing equipment. However, some may overlook its potential due to cost concerns or unfamiliarity.

Understanding its various uses can help businesses capitalize on this material's advantages. From architectural designs to industrial applications, stainless steel wire mesh plays a crucial role. Recognizing its benefits can drive innovation. Yet, there remains room for improvement in maximizing its potential. Each industry can explore unique applications, fostering further growth in this versatile field.

Applications in Industrial Filtration Systems

Stainless steel wire mesh plays a crucial role in industrial filtration systems. Its strength and corrosion resistance make it ideal for handling various materials. In many industries, it is essential for separating solids from liquids or gases. The mesh can be designed with different hole sizes. This flexibility allows for customized filtration solutions.

For instance, in water treatment plants, stainless steel mesh helps remove impurities. It prevents contaminants from passing through, ensuring clean water. In chemical processing, the mesh is used to filter out particulates. However, improper mesh size selection can lead to ineffective filtration. Companies sometimes overlook the significance of precise specifications, leading to operational issues.

Moreover, stainless steel wire mesh finds applications in food processing industries. It is often used in filtration systems for liquids like oils and juices. The mesh ensures hygiene while maintaining product quality. Yet, it is not immune to wear over time, necessitating regular inspections. Ignoring these checks could result in compromised filtration efficiency. Choosing the right mesh type and maintaining it are vital steps for optimal performance.

Use in Architectural Aesthetics and Design Elements

Stainless steel wire mesh is increasingly popular in architectural design. Its sleek, modern look adds sophistication to any space. Architects often use it for facades and railings. The mesh provides an industrial vibe while allowing light to filter through. This combination is visually striking. It creates depth and enhances the overall aesthetic.

Incorporating stainless steel wire mesh can bring unique challenges. For instance, how it interacts with surrounding materials matters. Sometimes, the mesh can overpower softer elements. Finding the right balance is crucial. Additionally, maintenance is a consideration. While stainless steel resists corrosion, it can still show dirt and fingerprints. Regular cleaning may be needed to maintain its shine. These factors require thoughtful planning to achieve the desired effect.

Moreover, stainless steel wire mesh is versatile. It can serve functional purposes, like security or privacy, without sacrificing beauty. Designers often experiment with different weave patterns. Each pattern can dramatically change its look. Choosing the right one is essential. The combination of aesthetics and utility can enrich architectural designs.

Role in Agriculture for Pest Control and Crop Protection

Stainless steel wire mesh plays a significant role in agriculture, particularly for pest control and crop protection. Farmers often face challenges from pests that threaten their yield. This is where wire mesh becomes invaluable. Its strong, durable structure can keep unwanted animals and insects away from crops without chemicals.

Using stainless steel mesh allows for good air circulation and sunlight penetration. These are critical for healthy plant growth. However, mesh can sometimes restrict access for beneficial insects like bees. The balance is important. Some farmers may hesitate, fearing a decrease in pollination.

Wire mesh not only protects crops but also supports sustainability. It reduces the need for pesticides, making farming more eco-friendly. It can be repurposed and reused multiple times. Farmers should consider the trade-offs when implementing this method. The choice of wire mesh should be based on specific needs and local conditions to maximize its effectiveness.

Implementation in Food Processing and Hygiene Standards

Stainless steel wire mesh plays a crucial role in the food processing industry. Its strength and durability make it a favorite for food safety applications. According to a report by the Food and Drug Administration, over 38% of foodborne illness outbreaks are linked to improper handling. This underscores the importance of hygiene in food processing.

In food handling, stainless steel wire mesh provides effective filtration and support. It prevents contaminants while allowing air circulation. This is vital for preserving the quality of food products. Many facilities are adopting a two-layer filtration system using this mesh. It significantly reduces bacteria presence, ensuring compliance with strict hygiene standards.

However, the use of stainless steel wire mesh is not without challenges. Regular maintenance is required to prevent corrosion and keep surfaces clean. A study indicated that 25% of processing failures stem from inadequate equipment upkeep. Therefore, while stainless steel wire mesh enhances food safety, it also demands ongoing attention to detail. This reflects a broader issue in the industry: even the best materials need proper management to be effective.

Importance in Security and Safety Fencing Solutions

Stainless steel wire mesh plays a vital role in security and safety fencing solutions. Its durability and strength make it an excellent choice for protective barriers. The mesh resists corrosion and can withstand harsh environments. This longevity is crucial for areas that face extreme weather conditions.

In many applications, such as schools, parks, and industrial sites, the safety of the public is paramount. Stainless steel mesh provides a robust barrier that deters intrusion. It can be easily installed in various configurations, offering flexibility for different needs. This adaptability is important when designing effective security measures.

However, choosing the right specifications can be a challenge. Not every mesh is suited for all environments. Imperfections in installation can lead to vulnerabilities. Hence, regular assessments and maintenance of the fencing are essential to ensure optimal protection. It's crucial to strike a balance between cost and security features.

Top 10 Uses of Stainless Steel Wire Mesh

This chart illustrates the importance level of various uses of stainless steel wire mesh in different industries. As seen, security fencing ranks the highest, reflecting its critical role in enhancing safety and security solutions.