QR Code

About Us

Products

Contact Us

Phone

Fax

0086-574-87527773

E-mail

Address

No 432 Zhenhai Middle Road, Luotuo Street, Zhenhai District, Ningbo City, Zhejiang China

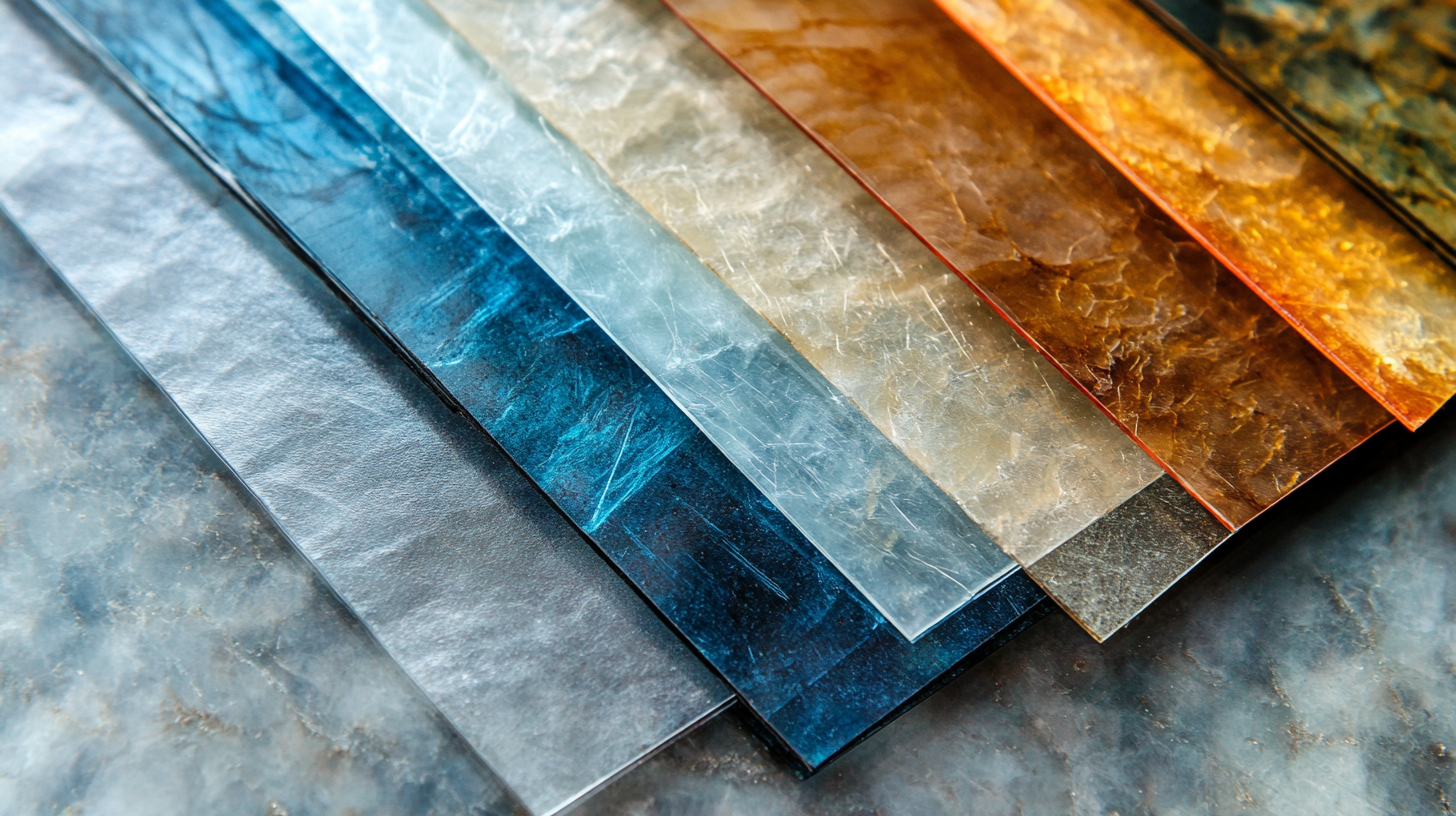

In the world of manufacturing and industrial applications, the demand for high-quality mica sheet use is ever-growing due to its remarkable properties, such as heat resistance, electrical insulation, and aesthetic appeal. When navigating the extensive marketplace for mica sheets, it’s crucial to recognize that not all suppliers are created equal. A meticulous selection process is essential to ensure that you collaborate with a reputable provider who can deliver premium materials that meet your specific needs. This blog post presents an ultimate checklist to help you identify the best mica sheet applications and offers valuable tips on sourcing top-notch suppliers.

By understanding the critical factors involved in choosing a reliable vendor, you can enhance your projects and achieve optimal results in your industry.

When selecting mica sheets for industrial applications, several key factors must be considered to ensure optimal performance and suitability for your specific needs. First and foremost is the thickness of the mica sheet. Different applications may require varying levels of insulation and strength, making it crucial to choose the right thickness to maintain efficiency and durability under operational conditions.

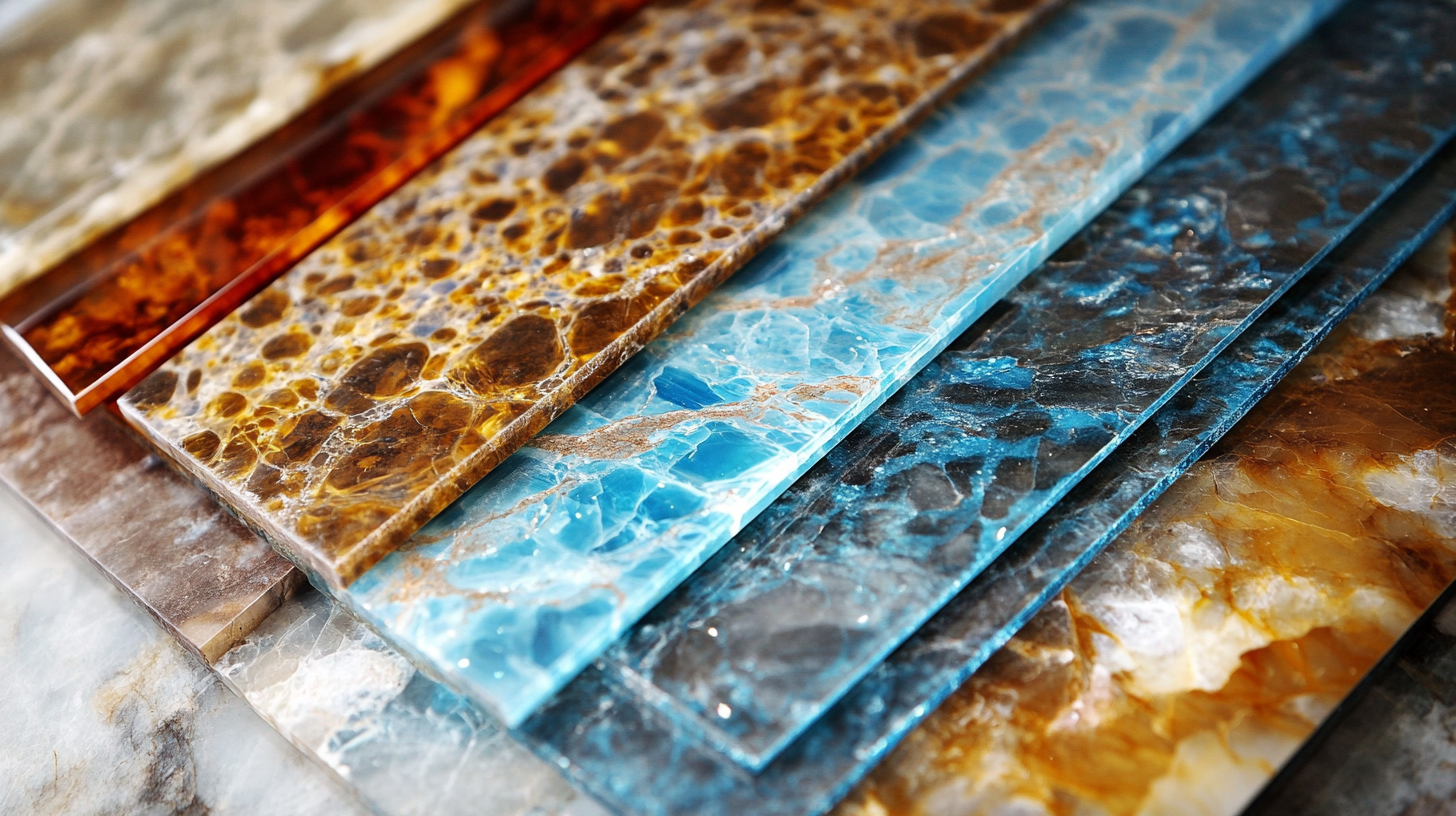

Another important factor to consider is the grade of mica. Mica sheets come in several grades, each with its unique properties and applications. For instance, electrical grade mica is essential for high-voltage applications, while thermal grade mica is preferred for insulation in heating elements. Understanding the specific requirements of your application will help guide you in selecting the appropriate grade.

Lastly, consider the source of the mica. Quality can vary significantly between manufacturers, so it’s essential to choose a reliable supplier known for high-grade mica. Ensuring that the mica sheets are sourced ethically and sustainably not only impacts the performance but also aligns with corporate social responsibility goals. By carefully evaluating these factors, you can make an informed decision that meets both your operational needs and industry standards.

Mica sheets play a crucial role in electrical and thermal insulation, particularly in high-performance applications. Their unique properties, such as excellent dielectric strength and resistance to thermal stresses, make them indispensable in settings like electric vehicles (EVs). According to recent market research, the global mica tape market is poised for significant growth, especially in electrical insulation applications, driven by the increasing demand for fire protection materials in EV battery designs. These materials are essential for mitigating risks associated with thermal runaway, a concern that has emerged as technology advances.

Tips: When selecting mica sheets for insulation purposes, consider their type—Phlogopite mica tape is known for superior thermal resistance, while Biotite tape offers excellent electrical insulation properties. It's crucial to match the specific requirements of your application to the right type of mica to enhance performance and safety.

Furthermore, as electrical components in vehicles become more compact yet powerful, the need for ultratough electrically insulating materials intensifies. Industries must prioritize sourcing sustainable and ethically produced mica, as concerns around child labor in mica mining have risen. Ensuring that suppliers adhere to responsible mining practices can safeguard brand integrity and promote social responsibility within the industry.

Mica sheets have gained prominence in various manufacturing processes, thanks to three significant advantages that set them apart. First, their exceptional thermal resistance makes them indispensable in industries such as electrical insulation. According to a report by MarketsandMarkets, the global electrical insulation materials market is projected to grow from USD 12.54 billion in 2020 to USD 16.74 billion by 2025, largely driven by the demand for reliable insulating materials like mica. Their ability to withstand high temperatures—up to 1000°C—ensures safety and longevity in applications ranging from transformers to heating elements.

Second, mica sheets offer unparalleled mechanical strength and resilience. This property is highlighted in a study by the Mica Industry Council, which indicates that mica composites can enhance product durability by 30% compared to standard materials. With their natural flexibility and low density, mica sheets can be easily molded into complex shapes, making them ideal for intricate designs in aerospace and automotive manufacturing, where both weight and strength are critical considerations.

Finally, mica's chemical resistance is another game-changing attribute. Data from the International Mica Association shows that mica's inert nature makes it resistant to chemical degradation, extending the lifespan of components in harsh environments. This reliability is crucial for sectors such as pharmaceuticals and food processing, where maintaining a sterile and contamination-free environment is paramount. As industries continue to seek efficient solutions, mica sheets stand out as a versatile option that delivers on performance and durability.

When selecting mica sheets for various applications, it's crucial to avoid common pitfalls that can lead to suboptimal performance and safety issues. One prevalent mistake is underestimating the importance of thermal stability. Mica sheets are increasingly used in industries where fire protection is paramount, especially in electric vehicles (EVs), where the fire safety of battery materials is under scrutiny. With the EV market projected to grow, it’s vital to choose mica sheets that can withstand high temperatures and provide effective insulation to prevent thermal runaway incidents.

Another common error is neglecting the specific electrical properties required for the intended application. Mica sheets possess excellent dielectric strength, which is critical in electrical insulation applications. According to industry reports, the demand for high-performance insulating materials in EV batteries is expected to rise significantly, highlighting the necessity of selecting the right mica sheets to ensure compliance with safety standards. Failure to assess these properties can compromise the entire system's integrity, leading to costly failures and safety hazards. As the market develops, informed decision-making will become increasingly essential to harness the full potential of mica sheets in advanced applications.

When considering materials for various applications, natural mica stands out as a superior choice compared to synthetic alternatives. Natural mica offers unique properties such as excellent thermal resistance, high dielectric strength, and outstanding flexibility, making it ideal for industries like electronics, cosmetics, and construction. A report by Transparency Market Research indicates that the global mica market is expected to reach $1.2 billion by 2027, which showcases the increasing demand for this versatile mineral in multiple sectors.

In addition to its functional benefits, natural mica is often favored for its environmental considerations. Unlike synthetic mica, which may involve complex chemical processes and produce harmful byproducts, natural mica is mined in a more eco-friendly manner. According to the Mineral Commodity Summaries, the extraction of natural mica adheres to stricter regulations that help minimize ecological impact, which is an important factor for companies prioritizing sustainability.

Tip: When selecting mica sheets for your application, ensure you verify the source of the natural mica. Choosing mica that complies with ethical mining practices can enhance your product's marketability. Tip: Always consider the specific requirements of your application—such as temperature resistance and electrical insulation properties—to determine the type of mica that will perform best.

0086-574-87527773

No 432 Zhenhai Middle Road, Luotuo Street, Zhenhai District, Ningbo City, Zhejiang China

Copyright © 2015-2024 Ningbo Nafty Sealing Materials Co., Ltd. All Rights Reserved.

| | | XML | Privacy Policy |

TradeManager

Skype

VKontakte