Water-repellent fabric may look like any other textile, but it’s engineered for protection.

But how does this smart fabric actually repel moisture without sacrificing comfort? In this article, we break down the science and craftsmanship behind water-repellent fabric sofas.

Discover what makes water-repellent fabric so effective, how they’re made, and why they’re a game-changer for homes that demand both style and practicality.

What are the Key Characteristics of Water-Repellent Fabric?

Water-repellent fabrics are specially designed to resist water penetration while maintaining comfort, breathability, and flexibility.

These qualities make them an excellent choice for everyday applications, especially in clothing, upholstery, and home textiles. Here are the key characteristics that set water-repellent fabrics apart:

1. Hydrophobic Surface

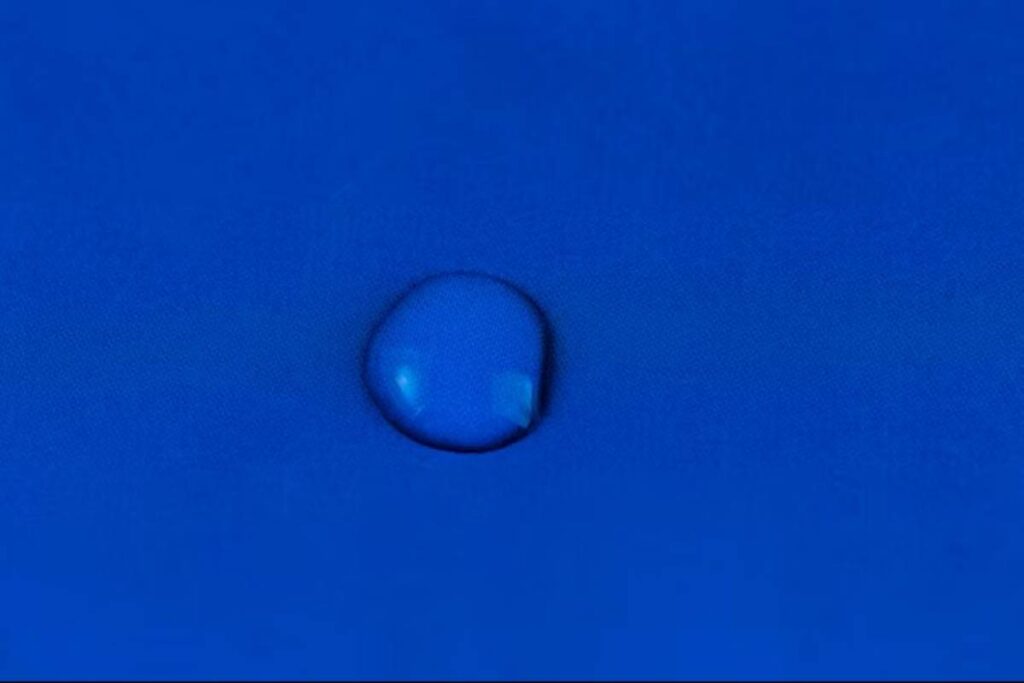

The core feature of water-repellent fabric is its hydrophobic (water-repelling) surface. This means that instead of soaking into the fabric, water droplets bead up and roll off.

This effect is often achieved through a chemical treatment, such as a durable water repellent (DWR) finish, or through the use of tightly woven synthetic fibres.

The result is fabric that stays drier for longer and resists light rain, spills, or splashes.

2. Breathability

Unlike many fully waterproof materials, water-repellent fabrics retain a high level of breathability.

It allows moisture vapour from the body (like sweat) to escape through the fabric, helping to regulate temperature and prevent that clammy, suffocating feeling often associated with non-breathable waterproof layers.

This makes water-repellent fabrics especially useful in garments, sofa coverings, and other items that require a balance of protection and comfort.

3. Lightweight

Water-repellent fabrics are typically lighter than fully waterproof alternatives, which often rely on thick coatings or laminates to block water completely.

The lighter weight not only enhances comfort, particularly in clothing and upholstery, but also makes the fabric easier to work with in design and manufacturing.

4. Flexibility

In addition to being lightweight, a water-repellent fabric is also more flexible than many waterproof materials, which can be stiff or rubbery due to heavy coatings like PVC or multiple membrane layers.

The added flexibility improves wearability in garments and creates a softer, more natural feel when used in upholstery or home textiles.

Together, these characteristics make water-repellent fabrics an ideal middle ground between comfort and protection.

They offer enough resistance to handle light moisture while remaining breathable, soft, and user-friendly.

Read More: Fabric for Sofa: Ultimate Guide to Selecting the Best Material

How is a Water-Repellent Fabric Sofa Made?

1. Raw Material Selection

The process begins with selecting the right fibres. Most water-repellent upholstery fabrics are made from synthetic fibres like polyester, nylon, or acrylic.

These materials are inherently less absorbent than natural fibres such as cotton and offer excellent durability, colour retention, and resistance to wear.

Occasionally, fibre blends are used; synthetic fibres mixed with a small amount of natural fibres to improve texture or achieve a particular aesthetic.

However, the water-repellent properties mainly come from the synthetic content and finishing treatments.

2. Yarn Production (Spinning)

Once the fibres are chosen, they are processed into yarns. This involves cleaning, carding (aligning the fibres), and spinning them into threads of varying thicknesses and strengths.

The spinning stage determines much of the fabric’s durability, feel, and visual consistency.

3. Fabric Construction

The yarns are then weaved to construct the fabric. The type of weave (plain, twill, jacquard, etc.) affects the fabric’s texture, strength, and moisture resistance.

A tighter weave generally offers better protection against water penetration.

4. Pre-Treatment and Dyeing/Printing

After weaving, the fabric (called “greige goods”) must be cleaned to remove oils, sizing agents, and other residues from production.

This step is essential, as leftover substances can interfere with later water-repellent treatments. The cleaned fabric is then dyed or printed to achieve the final colour or pattern.

5. Water-Repellent Finish (DWR) Application

This is the most critical stage in making the fabric water-repellent. A Durable Water Repellent (DWR) treatment is applied to the fabric’s surface.

DWR contains hydrophobic compounds that cause water to bead and roll off the fabric instead of being absorbed.

Common application methods include:

- Padding/Immersion: The fabric is submerged in a vat of DWR solution to ensure full saturation.

- Spraying: The DWR solution is sprayed onto one or both sides of the fabric for uniform coverage.

- Knife Coating: A thin layer is applied with a blade or roller for precision and control.

6. Curing (Heat Treatment)

After application, the fabric goes through a curing process. It involves passing the fabric through heated chambers to activate and bond the DWR chemicals to the fibres.

This heat bonding is what makes the treatment durable, allowing it to resist water through regular use and cleaning.

7. Final Outcome

The result is a durable, flexible, and comfortable fabric that not only looks great but also protects against spills and stains.

When upholstered onto high-quality sofa frames, water-repellent fabric helps create furniture that is both stylish and practical, ideal for homes with children, pets, or frequent guests.

Read More: High-Density Foam Sofas: All You Need to Know Before You Buy

What are the Benefits of a Water-Repellent Fabric Sofa?

1. Superior Spill and Stain Resistance

The most immediate advantage of a water-repellent sofa is its ability to protect against accidental spills

Liquids such as coffee, juice, or sauces bead up on the surface instead of soaking into the fabric, giving you valuable time to wipe or blot the mess before it becomes a permanent stain.

This feature is especially useful for households with children, pets, or a fast-paced lifestyle, where quick cleanups can make a big difference.

2. Enhanced Durability and Longevity

Water-repellent fabrics do more than resist stains. They protect the sofa’s internal components as well.

By preventing moisture from seeping into the foam cushions or internal frame, they help guard against hidden damage that could compromise the structure over time.

In humid environments, where trapped moisture can lead to mould, mildew, and unpleasant odours, this added protection is invaluable.

3. Improved Hygiene

Keeping the fabric surface dry also contributes to a cleaner, healthier home.

Water-repellent sofas reduce the chances of allergen buildup by creating a less inviting environment for dust mites and other moisture-loving particles.

Less moisture also discourages bacterial growth, helping you maintain a more hygienic living space, especially important in homes with allergy sufferers or young children.

4. Comfort Without Compromise

Thanks to advances in textile technology, many modern water-repellent treatments are applied in thin, flexible layers that don’t alter the natural feel of the fabric.

This means your sofa can still be soft, breathable, and comfortable, without the “sticky” sensation sometimes associated with waterproof materials.

Read More: 5 Best Sofa Fabric for Hot Weather

Upholstery for the Modern Home

From surprise spills to muddy paws, a lot can happen on your sofa. That’s why choosing one with water-repellent fabric just makes sense.

It keeps messes on the surface, protects what’s inside, and stays comfortable day after day.

At Kintex, a leading upholstery fabric supplier in Malaysia, we offer a selection of high-quality materials tailored to modern living.

We’re here to help you choose fabrics that don’t just look good — but perform beautifully. Explore Kintex’s upholstery fabric collection today.