Imagine sinking into a plush mattress after a long day or opening a refrigerator that keeps your food perfectly chilled. What do all these experiences have in common? PU foam.

From everyday household products to high-performance industrial applications, PU foam enhances comfort, improves insulation, and adds durability to countless products. But what exactly is it, and why is it such a versatile material?

In this guide, we’ll explore the science behind PU foam, the different types available, and the benefits that make it an essential component across industries

Whether you’re interested in its role in furniture, construction, automotive design, or beyond, this comprehensive breakdown will give you a deeper understanding of this innovative material.

What is PU Foam?

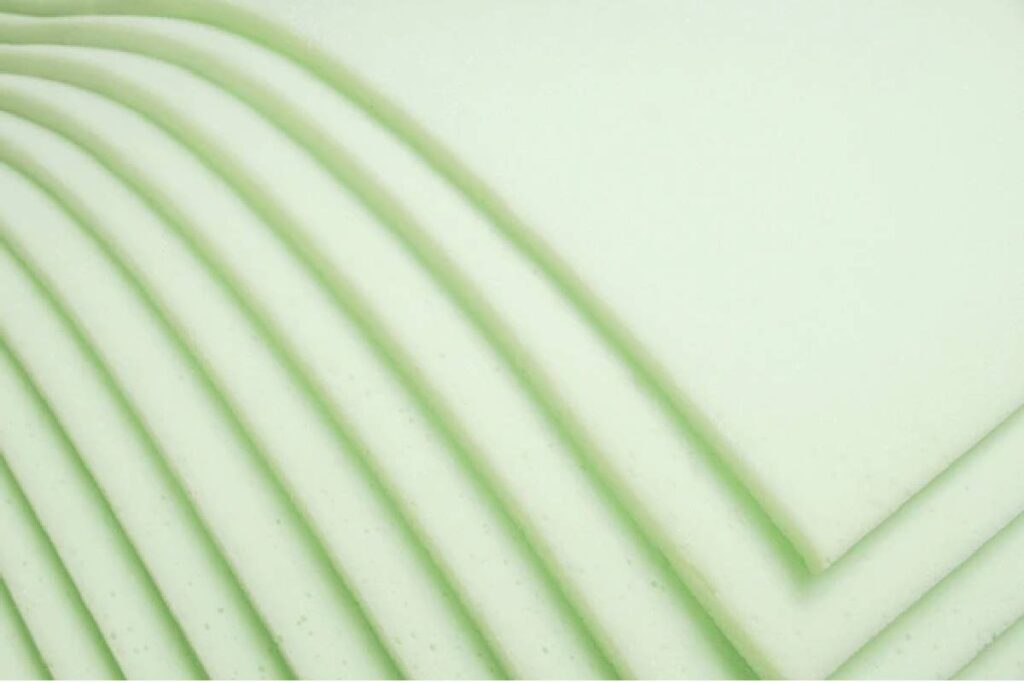

Source: SIEKOS

Polyurethane foam (PU foam) is a synthetic material produced through a chemical reaction between polyols and isocyanates.

First developed in 1937, this process results in a cellular structure that can be modified based on specific formulations and requirements.

The production of PU foam involves carefully controlled conditions, including temperature, pressure, and the use of catalysts, surfactants, and blowing agents to regulate cell formation and density.

The composition of PU foam can be adjusted to achieve different physical properties, such as varying levels of hardness, elasticity, and resistance to environmental factors.

Depending on the formulation, the foam’s density and structure can be fine-tuned for specific applications, making it a highly customisable material.

Additionally, PU foam manufacturing can incorporate additives to enhance characteristics like flame resistance, UV stability, or moisture resistance.

Due to its adaptability and efficient production process, PU foam has become an integral material in various industries.

Advances in chemical engineering continue to refine its properties, ensuring its continued relevance in modern applications.

What are the Types of PU Foam?

PU foam is available in different types, each designed to meet specific performance requirements. The two primary categories are:

1. Flexible PU Foam (FPUF)

Flexible polyurethane foam features an open-cell structure, allowing it to be soft, compressible, and resilient. This flexibility makes it ideal for applications requiring cushioning, support, and impact absorption.

Some of its common uses include:

- Mattresses: Provides comfort and pressure relief, often used in memory foam and hybrid mattress designs.

- Upholstered Furniture: Used in sofas, chairs, and cushions for enhanced seating comfort.

- Automotive Seating: Improves ergonomic support and vibration absorption in vehicle interiors.

- Athletic Equipment: Found in protective gear, padding, and sports mats.

- Packaging Materials: Used to protect fragile goods during transportation.

Additionally, it is popular for its sound absorption properties, making it an effective material for acoustic insulation in recording studios, theatres, and offices.

2. Rigid PU Foam

Rigid polyurethane foam is characterised by a closed-cell structure, which gives it excellent thermal insulation properties. It is commonly used in:

- Building Insulation: Applied in walls, roofs, and floors to enhance energy efficiency.

- Refrigeration Systems: Provides insulation for refrigerators, freezers, and cold storage units.

- Structural Applications: Used in composite panels and load-bearing insulation materials.

Rigid PU foam is an essential material in modern construction and energy-efficient design, helping reduce heat transfer and lower energy costs.

Its durability and moisture resistance also contribute to its widespread use in climate control solutions.

Read More: Refurbish Sofa Guide: When Should I Refurbish My Sofa?

What are the Benefits of PU Foam?

With its combination of durability, insulation capabilities, and adaptability, PU foam continues to be a preferred material in construction, automotive, furniture, and many other industries.

1. Lightweight

PU foam is incredibly lightweight, which makes it easy to handle, transport, and install without adding unnecessary bulk or weight to structures.

Despite its low density, it maintains high strength and resilience, allowing it to support loads and withstand pressure without easily deforming or breaking.

This balance of strength and weight makes it an essential material in applications where both durability and ease of use are important.

2. Exceptional Durability

Unlike many other cushioning and insulating materials, PU foam has a long lifespan due to its resistance to physical wear and environmental factors.

It retains its shape and performance over time, making it an economical choice for long-term applications such as furniture padding, insulation panels, and automotive interiors.

3. Superior Thermal Insulation

One of its standout properties is its ability to minimise heat transfer.

Its low thermal conductivity makes it an excellent insulator, reducing energy loss in buildings, refrigeration systems, and industrial applications.

By preventing heat exchange, it helps maintain indoor temperatures, improving energy efficiency and reducing heating and cooling costs.

4. Moisture and Mould Resistance

Certain types of PU foam, particularly those with a closed-cell structure, have excellent moisture resistance.

This prevents water absorption and minimises the risk of mould and mildew growth, which can compromise the material’s integrity over time.

Its resistance to moisture makes it particularly useful in environments with high humidity or exposure to liquids, such as construction, marine applications, and refrigeration systems.

5. Ageing and Weather Resistance

PU foam maintains its physical properties even after prolonged exposure to environmental conditions such as UV radiation, temperature fluctuations, and humidity.

Unlike some materials that deteriorate, harden, or crack over time, PU foam retains its flexibility and insulating properties, ensuring long-term reliability.

Read More: Reupholstering Furniture: A Step-By-Step Guide

Kintex PU Foam: Versatile, Reliable, and Built to Last

PU foam is a game-changer in multiple industries, offering the perfect balance of comfort, durability, and insulation.

Whether it’s flexible PU foam for plush seating and mattresses or rigid PU foam for high-performance insulation, this material continues to prove its value in everyday applications.

For high-quality PU foam that enhances comfort and performance, Kintex is a trusted supplier in Malaysia. Our expertly curated selection ensures you get the best materials for your furniture and upholstery needs.

Explore our range of PU foam today and elevate your products with premium comfort and durability.